Armilite.. Thanks for your input, but this damage it not from detonation. I am sure you will agree if you look close. I did do a compression test when I installed it, 120 in both, which is 30 pounds low. I have learned since this incident that the company involved cuts chambers to reduce compression to avoid warranty claims from people using cheap fuel.

You can see the perfectly round impressions left by ends of the steel pins. The irregular shaped impressions were caused by bits of aluminum that were scrapped from the crankcase as the pins were forced between the crank and the case during their violent escape out of the engine and into the lake!

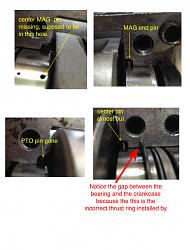

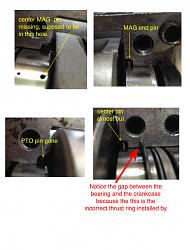

The damage was caused when two bearing alignment pics worked their way out of the crank bearings because the case halves were held apart by an oversized thrust ring that was installed by a big name PWC engine rebuilder. Whoever assembled the engine HAD to know they had something wrong as there was WAY too much sealant between the case halves.

I would not have even known the pins came out if one had not smashed the sparkplug closed. While it did run rough for a few seconds, I thought I had sucked up a stick or mud as I was running slow in the no wake zone. The second pin came out at speed and it instantly began running on one cylinder.

I did contact that builder even though the engine was out of warranty, assuming they might want to know what they were installing incorrect parts. Thinking I might able to save someone else this aggravation. Due to their indignant response to the well documented obvious error, I will never purchase another part from them.

The engine is from a 1998 TigerShark TS770L. It is one from a pair of identical boats that I bought from a guy who asked me to repair them. One had been run with no oil, the other had been damaged from improper winterizing. When I gave him the $4000.00 estimate to replace the engines and broken exhaust manifold in his boats, he sold them to me cheap. Since the complete rebuilt engine was only $20.00 more than all of the parts it would take to rebuild it correctly, I opted to purchase it rebuilt. My mistake!!! I rebuilt the second engine myself as it was not hurt as badly. It is running just fine and was in fact quicker than the rebuilt one.

I always use fresh Sunoco Ultra 93 octane fuel in my boats, then use whatever is left over over in my truck at the end of the season.

John

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks