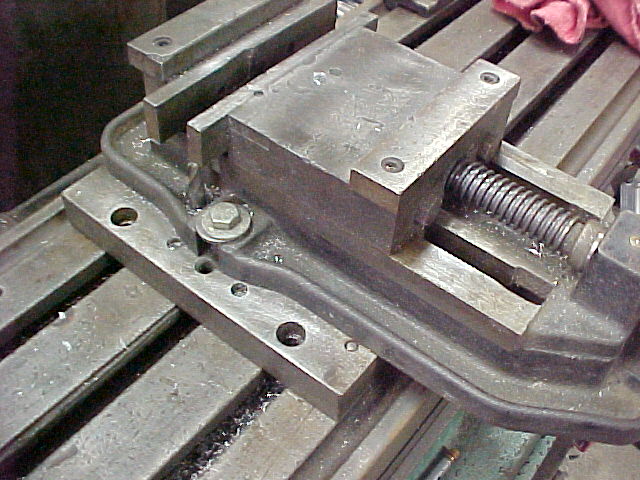

My milling vise is mounted to a steel plate. The vise is bolted and doweled to the plate.

The plate is also doweled to the table with 2 1/4" pins.

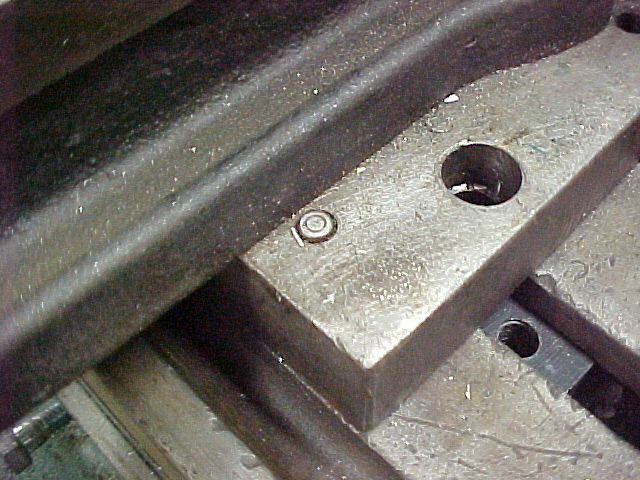

One in the left corner...

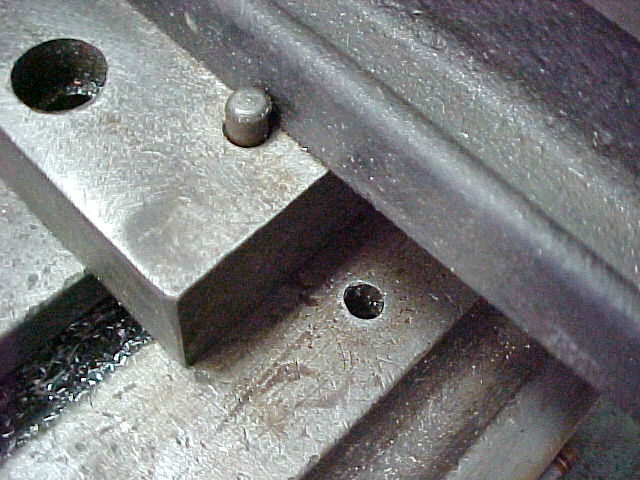

And one in the right corner...

Here you can see the pin and the hole in the table.

Pinning the vise and the plate makes for very easy tool changes. I need to do this to the rotary table also.

Mark

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks