Hi,

Here is my low tech method for turning an MT2 morse taper with the compound slide.

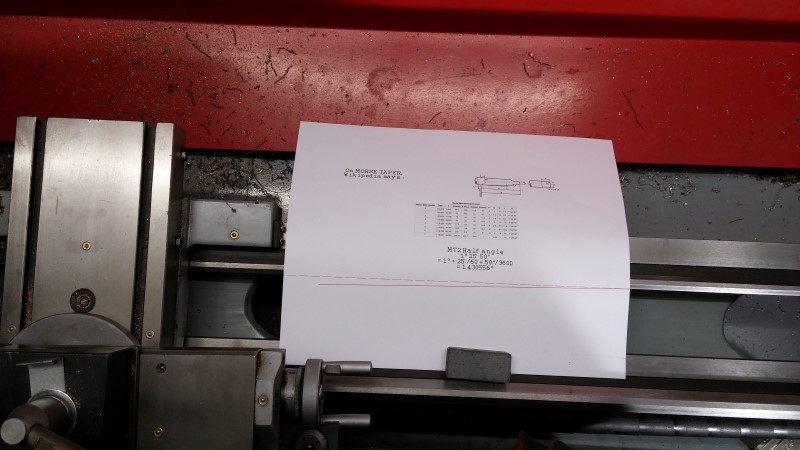

I setup the angle of my compound slide just by pressing on its side a ruler, and eye balling, looking vertically, the line drawn on a template paper.

The paper is drawn with the CAD software, it shows the axis, which is carefully aligned with the edge of one of the ways of the lathe. The drawing shows in red the half angle of the taper, which needs to be exactly aligned with the above ruler, so with the the compound slide.

Here are some pictures :

The template is hold down with a magnet.

Looking down vertically, the ruler must be aligned with the red line.

Using my plane adjusting hammer to gently tap the slide for fine tuning.

It can be used also for checking the angle of a test piece.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Do you play guitar as well?

Do you play guitar as well?

Bookmarks