Captain's Lathe 2nd Mod

Hi everyone,

This is 2nd and most important modification of my lathe (11 x 26, bigger brother of Grizzly G0602).

In order to make compound more rigid and also to enable use of bigger cutting tools, I made 4 bolts compound clamp and by the same time I lowered top slide for almost 5 mm. That allows use of bigger 4-way tool post and 16 x 16 mm cutting tools.

Both; compound clamp and new pivoting base were made from 25 mm high tensile AH36 (shipbuilding) steel plate. In order to make it more rigid,

I made new pivoting base which is bigger and which has recess for compound slide pivoting base. Compound clamp is bolted down with four M8 x 30 bolts.

Picture 01

Original (very bad) design is 2 bolts compound clamp with bolts at wrong places. There is a lot of flexing, vibrations and chatter.

Picture 02

New 4 bolts compound clamp and new beefier 4-way tool post.

I have no intention of installing QCTP, as for the last 30 years or so I was working on various heavy duty lathes with 4-way tool post. Shimming is not a problem at all, especially if the same size tools are used. For this tool post and 16 x 16 mm tools I need 2 mm shim. For 16 x 16 mm boring bar holder I need 9 mm high shimming.

Picture 03

My complement of 16 x 16 cutting tools. I think I am done with buying turning tools. Only inserts from time to time.

Picture 04

Drawing / clamp + 4-way tool post

Pictures 05 and 06

New beefy 4-way tool post compared with old low one. Observe that new tool post is unfinished rough product. This 75 x 75 mm tool post was purchased via Taobao in China for 12.50 USD. It is not completed product. Made of extra hard material and took me long time to square and polish it.

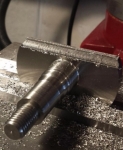

Picture 07

T-Bolt for tool post was made from one piece of 316 stainless steel round bar, diameter 70 mm.

Picture 08

Squaring and drilling of compound clamp.

Picture 09

Drilling and threading of cross slide. (M8 thread)

Picture 10

Compound clamp; top view and bottom view

Picture 11

Pivoting base; top view and bottom view

Picture 12

Compound slide and compound clamp parts and assembled

Picture 13

Dial ring and set screw. As the pitch of lead screw is metric (1.5 mm)

and numbers on dial ring are in thousands of inch, I used dymo tape and

print numbers in mm. 0 – 3 mm for diameter reading. Also installed set screw as original design with some weak leaf spring inside was disaster. Dial ring was rotating freely.

Picture 14

Clearance between handles. Top slide could not be lowered any more.

Picture 15

Tool post handle; made of stainless steel and Chinese chrome plated handle and M18 closed end cup nut on top of handle will avoid hand injuries.

Picture 16

Three 3 mm shims are required for 16 x 16 mm boring bar holder.

It is impossible to use this boring bar holder or bigger boring bars in old turret tool post or any size QCTP (AXA, BXA, 100, 200 etc) which are suitable for this size lathe. Also this cheap and extra hard 4-way turret tool post is (in my opinion) much better choice than any Aloris, Dorian, Phase II or cheaper Chinese wedge or piston type quick change tool posts. They are simply overrated.

Hope that above will help someone to improve his lathe and make right decision which tool post to buy.

Next post will be tailstock cam lock. Already done and pictures taken.

LMMasterMariner

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks