Gasket alternative grooving tool

For some years now I have stopped using gaskets on my engines after deciding that they were never there for my benefit but used to compensate for poor manufacturing, and in my experience always leak after a while.

I am talking of course about old British iron and not modern machines, my Triumph twin has only a cyl head and base gasket as they are dissimilar metals.

I know I am not the first to do this, but this is my method and can honestly say that non of my old bikes leak oil after running for a few years even with HTF fluid in chaincases etc.

It also removes the need to re-tighten after first running.

Faces have to be flat and a bit of lapping may be necessary, after that a groove is cut in one half and this gives a means of retaining the jointing compound (I use Hylomar Blue as its good enough for Rolls Royce).

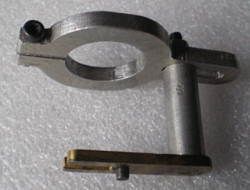

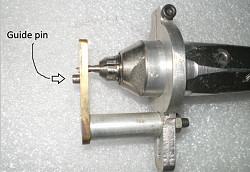

The obvious tool to use is a Dremel type device, mine is made from an old hand piece from a flexi drive connected to a 12 volt drill motor but the important bit is controlling the the cutter as its a freehand process.

A simple guide attachment was made and a cutter from a 1/8 centre drill ground to a D bit shape does the job, about 15 thou deep is enough.

It is important to work from the inside face so any slip ups do no harm and just like milling,direction of cut has a bearing.

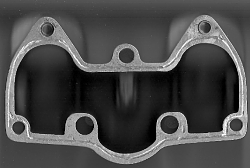

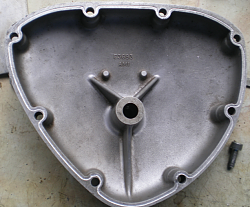

The first pic was freehand and I just about got away with it, the second was guided with the attachment and the difference is pretty obvious.

I hope this helps in keeping the oil where it should be.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote I noticed you stayed a bit south of center line too which is smart in my book. Turnips are notorious leakers!! Back when I built mine I did lap all the faces but used an amazing product I found back then called Kawasaki Bond...best sealant I ever used...had a silver look/compound in it and it came apart well and cleaned up easily. Blue and Red silicone was just out then and never did have much luck with it until the formulas improved. The early KB I used is Long gone now and haven't tried the newer silicone based version...but like you say if Hylomar Blue is good enough for Rolls...it'll work for me. Haven't heard of that before but will have a look for it over here.

I noticed you stayed a bit south of center line too which is smart in my book. Turnips are notorious leakers!! Back when I built mine I did lap all the faces but used an amazing product I found back then called Kawasaki Bond...best sealant I ever used...had a silver look/compound in it and it came apart well and cleaned up easily. Blue and Red silicone was just out then and never did have much luck with it until the formulas improved. The early KB I used is Long gone now and haven't tried the newer silicone based version...but like you say if Hylomar Blue is good enough for Rolls...it'll work for me. Haven't heard of that before but will have a look for it over here.

Bookmarks