Thanks buddy.

I planned to make wide scissor jack and use it for straightening. I could swap jacks when necessary, that was also one reason why i placed jack down.

With thinner material i could use power drill for rolling, with thicker material handle.

I think it would work nicely. Tought.. i don't need to straighten thicker than 6-8mm materials, i thick somewhat 2-3 ton power would be enough.

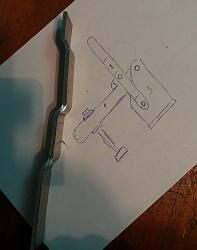

Btw. Made first parts to my "No weld quick action hold down clamps". Brake seems to work just like i hoped.

Last edited by Tuomas; Jan 15, 2018 at 11:59 PM.

If you're ever worried that you'll have to stop building tools after you finish your latest tool build, just look at Tuomas's builds. This is the strategy of a skilled toolbuilder - simply make new tools for the tools you've already built or own. All of these accessories are for just three tools: a drill press, an angle grinder, and a Dremel.

HomemadeTools.net founder (2012) and CEO

Join thousands of us, and start building your own tools today.

Thanks Jon!

Simple pipe bending attachment.

Material:

Surplus steel, nylon replacement heads from the dead blow hammer, bolts.

It can be used to bend pipes and rods to 12mm diameter. ( grooves on the dies are with 12mm diameter )

Same idea works with bigger pipes too, radius of the center die needs to be bigger than this one tough.

Next add is a roller bender.

Last edited by Tuomas; Jan 16, 2018 at 02:34 PM.

charles scozzari (Dec 12, 2022), PJs (Jan 16, 2018), rdarrylb (Dec 12, 2022), that_other_guy (Aug 18, 2023)

Last edited by Tuomas; Jan 17, 2018 at 01:33 AM.

PJs (Jan 18, 2018)

"Die" is a correct term; applied on tools that cut or form in conjunction with a punch, called a "die set".

Sometimes a distinction is made, naming them according to function, especially "forming die". Dies that cut are a bit more common, and "die" is sufficient.

While a metal brake forms by clamping and bending, a press style exhibits a more distinct entry of a punch into a die.

Large dies performing a series of operations, are "progressive". Usually fed from long rolls of material, not necessarily just flat stock, according to finished part.

'Drawing' is a forming operation too, common parts are door knobs, drawer handles, firearm cartridges...The stock can be sheet or thick slugs.

There are dies doing a set of operations, often hand fed from station to station, of individual pieces. These work in many instances; such as long parts with each end being trimmed in a radius. One I built, made a metal reinforcement for truck mud flaps. Upper edge had long bevels left and right, lower side had two radius's. It also stamped the manufacturer name in the middle. That company didn't have a wide press with sufficient tonnage for a single hit, the build accommodated that. Two hits, cut one bevel and radius left then right, stamping occurred once with the right side.

The subject of types of dies go far deeper than this!

Sincerely,

Toolmaker51

...we'll learn more by wandering than searching...

Tuomas (Jan 18, 2018)

Tuomas (Jan 18, 2018)

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks