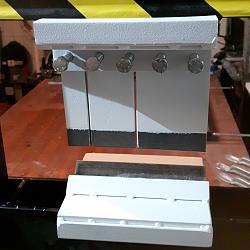

Finger dies.

1,2 and 3" wide dies. Gives somewhat enough possibilities to mix needed widht.

10mm plate with 20mm x 20mm bar on both sides.

Dies are placed between bars and secured with M8 bolts.

Intentionally too long bolts, i like its easier to tighten/ loosen over long bolts with ratched.

Dies are also 10mm plate. Bending edge is grinded to 45 degree angle from both sides and slightly rounded, to avoid deep marks on workpiece.

Material is mild steel, and dies medium carbon steel AISI 1029

Made this tool some time ago. Its for drilling to the edges of the plates.

I marked placement of the holes before welding. Straightened the baseplate with press after welding.

Then drilled 6.8mm holes

Threaded with M8 tap.

Cleaned and painted.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks