Hi guys,

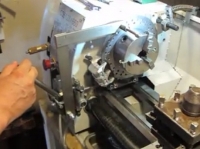

This is just addition to lathe chuck brake, but both combined make perfect tool.

Consists of the following parts:

- Lathe Chuck Brake (already described)

- Indexing disc

- Bar

- Indexing pin

- Locking piece

Indexing Disc

=============

It is actually brake / indexing disc as it has 2 purposes.

Making of that disc is described in my post 'Lathe Chuck Brake' and drilling

of the holes on it was done as follows:

1. Brake / Indexing disc was mounted onto lathe chuck with three 8mm bolts.

2. 5" four jaws scroll chuck was mounted onto 6" rotary table. TIR 1/100 mm.

3. Both chucks were connected with perfectly straight 22 mm s.steel round bar.

TIR at lathe chuck = 2/100 mm, which is almost negligible for this project.

4. First I drilled inner circle of holes (24 holes) with 15/64" drill and afterwards milled

holes with 1/4" end mill. Then outer circle of holes (30 holes) was done the same way.

With these 2 rows of holes I have the following divisions: 2, 3, 4, 5, 6, 8, 10, 12, 15, 24 and 30.

Bar

===

Made from 30 x 5mm stainless steel flat bar; two bars connected at 90 deg angle.

Guider for indexing pin made from 15 mm s.s. round bar, drilled with 1/4",

one end threaded with M12 thread and screwed onto flat bar.

Indexing pin

============

Made from S.S. 8mm round bar. Partly turned to 6.35 mm

Locking Piece

=============

Made from steel 10mm bolt. Head of the bolt was milled in order to fit behind the brake block.

And the most important for the end:

Chuck brake keeps chuck fully locked in desired position.

Regards

LMMasterMariner

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks