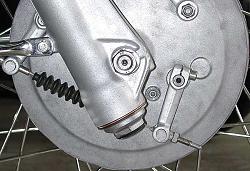

I had a clutch basket that had become notched but was otherwise ok, tooth and bearing track wear was minimal so I decided to try and reclaim it and keep as a spare (nothing to loose).

The width of the slots is not critical as long as they are smooth so I planed out the wear in the lathe.

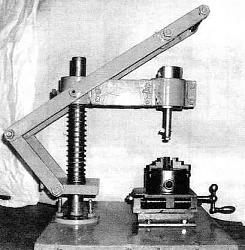

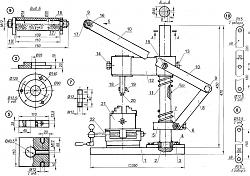

I used the topslide as a hand operated ram which has worked well in the past for keyways etc and with a suitable tool in a boring bar and indexed it turned out well.

This was actually done on a faceplate but I forgot to take photos at the time so I mocked it up again in the chuck as an after thought.

This is maybe not best approach for easily replaceable parts but this was done as an exercise for when there is no option, and anyway I can never throw anything away.

I have made many things in the past but never thought to record them until joining HMT.

Regards

Olderdan

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks