It's helpful to distinguish between "locking" and "retention" when discussing fasteners; these terms tend to be used interchangeably when in fact, they're entirely separate functions.

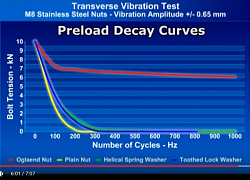

When speaking of a "locking" feature, this is a mechanism intended to prevent a fastener from loosening or otherwise disrupting the installed preload (otherwise known as "torque"). A "retention"" feature does not prevent a fastener from loosening. Its purpose is to retain or capture the fastener (once loose) from separating from its mating part and causing further damage. Cotter pins, safety wire, [lock washers] and related mechanisms will NOT prevent a fastener from loosening.

As noted, a good quality lock washer will, once relaxed (fastener broken free from its installed preload), resist further loosening of the fastener (acting as a retention mechanism). Fully compressed with the correct fastener preload, though, it acts as a simple flat washer with no locking attributes.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks