Thanks for the link. Yes, the suggested Mini LED would make for a much nicer and compact device. Although I am not fond of any button style battery since they tend to be more expensive than your garden variety AAA. Good idea about reducing brightness on the HF light. The HF light is about .995" diameter which I assume is a bit less than the loupe. I'm not sure which light I will use. Also, ambient light, through an empty hole(s) may be enough. I would aim the hole(s) at the cross-hair area. Anyway, a nice project and your great idea I will get to eventually.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

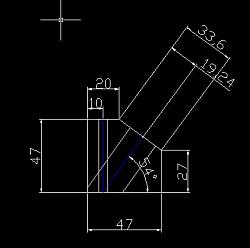

my next question was going to be how to get a 20mm diameter hole for the optic. Biggest I have is a 16.

my next question was going to be how to get a 20mm diameter hole for the optic. Biggest I have is a 16.

Bookmarks