I'm running out of superlatives Doug, but it

is beautiful and

works like a charm. That fit on the pin was @¿@...nice, to say the least. Kind of a dedicated spindexer but the the no-lash nylon washer and gravity latch are excellent touches.

I'm not however running out of questions. ~

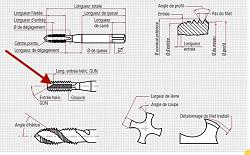

~ Always been curious as to the price of reamers, (expensive in my book) is it worth sharpening the flute to an undersized dimension?? I get that the cutting is done at the entry and the flutes act more as a hone, but have seen used ones with seriously worn or dinked flutes in flea markets and garage sales, and wondered if concentricity becomes an issue on a deeper ream due to the wear? Or maybe runout in the drive spindle causing it?

Always thankful for your posts!!

PJ

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

~ Always been curious as to the price of reamers, (expensive in my book) is it worth sharpening the flute to an undersized dimension?? I get that the cutting is done at the entry and the flutes act more as a hone, but have seen used ones with seriously worn or dinked flutes in flea markets and garage sales, and wondered if concentricity becomes an issue on a deeper ream due to the wear? Or maybe runout in the drive spindle causing it?

~ Always been curious as to the price of reamers, (expensive in my book) is it worth sharpening the flute to an undersized dimension?? I get that the cutting is done at the entry and the flutes act more as a hone, but have seen used ones with seriously worn or dinked flutes in flea markets and garage sales, and wondered if concentricity becomes an issue on a deeper ream due to the wear? Or maybe runout in the drive spindle causing it?

Bookmarks