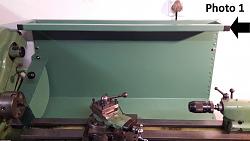

Although this splash guard was made for my Myford ML7R long bed lathe, the design could probably be adapted for many other lathes. The splash guard consists of a welded frame (25x25 mm square tubing) and a surplus back plate from a set of steel shelves (Photo 1 and Fig 1). The plate is affixed to the frame with pop rivets. The splash guard is 550 mm high and 912 mm wide.

I had a few basic requirements:

1. The guard had to include storage space for often used tools (Photo 1). I keep the tools, grouped together by use (e.g. chuck keys), in margarine tubs placed on the shelf. This way I do not have to rummage around on the shelf for tools while stretching over a running late, but rather remove the whole tub when selecting tools.

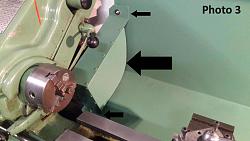

2. The motor had to be protected from swarf, but still be easily accessible for maintenance. The frame was drilled and tapped and the motor splash guard was fixed to the main splash guard with hex socket bolts to allow easy removal (Photo 3).

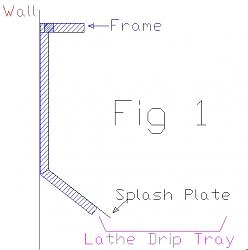

3. I wanted a sturdy splash guard and did not want to increase noise levels through lathe vibrations transmitted to the splash guard. The frame of the guard is therefore bolted to the wall (Photos 2 and 4) and is not in contact with the lathe or its drip tray. The bottom of the guard overhangs the drip tray, to catch drips of splashed fluids (Fig 1 and Photo 5).

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks