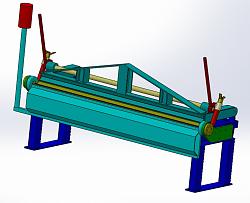

this is not a new tool but it will hardly resemble the itself.

I made this about 3 years ago to do 1 little job then after finishing the job it got put on the back burner for completion

http://www.homemadetools.net/forum/7...0277#post57046

So for the past month I have been time allowing making tools and parts to finish it up I still might not get it completed as much as I want but at least it is now far enough along to be considered work in progress plus it is right in my way which makes me more inclined to do some work on it .

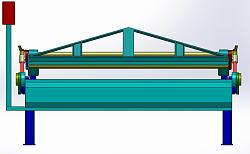

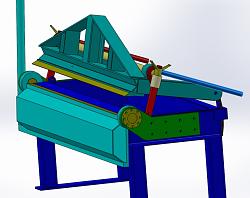

As you can see it was about as rudimentary of a metal break as possible

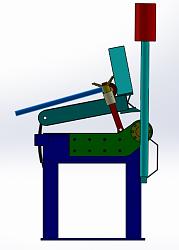

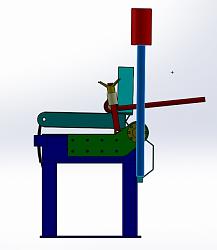

So first things first the gate or swing beam had to go and a top clamp was needed

then a new gate had to be made

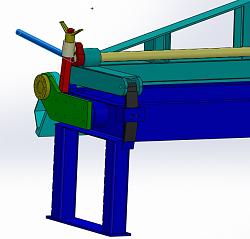

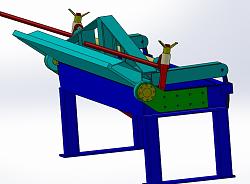

next the parts for the pivot. I have a large stack of these I think they were once used as casting molds that a guy used to make small train wheels

the bore was too large for my 6212 bearings so I welded them up then machined them out to the depth of 2 bearings

Some left over cut offs from the Forklift carriage will become the mount base which the gate pivot mounts will bolt to

you can see how tough Caterpillar metal is by the sparks at least 120,000 PSI tensile

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks