I'm always nervous wiring my good VOM in series into a circuit to measure current. Another way to measure current is to measure voltage across a resistor that is series wired into the circuit in question. This way the VOM remains in high impedance mode and so is less susceptible to damage.

Most circuits will not be adversely affected if the series resistor is very small in comparison to the circuit resistance itself. OTOH, the resistor must be large enough to produce an easily measured voltage when the current is flowing through it.

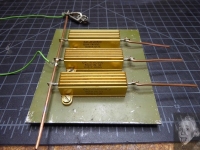

I acquired three 50 watt, 1% resistors in resistances of 0.1, 1.0, and 10.0 ohms and attached them to a large aluminum plate to act as a heat sink.

Given 50 watt capability, the maximum current and associated voltage for each resistor is...

ohms amps volts

0.1 22.4 2.24

1.0 7.1 7.1

10.0 2.24 22.4

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks