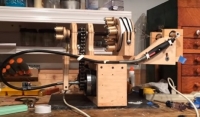

I used a Kitchen Aid mix master motor Its 10 speed and low rpm with lots of tourk. the only parts I purchased were two sprockets, the rest was stuff from around the shop. The main shaft was from a paper towl holder. For the planitary system I used a 4 in. hard rubber weel from a Westinghouse elevator counterweight roller guide. As a elevator mechanic I come across alot of stuff that can be repurposed. Around the roller are four pieces of 3/4 in. tubing that fit snugley inside a piece of 6 in. pvc coupling. Thay are held in place by two pieces of hard board that are drilled out to freely rotate and are held to each other with some pieces of dowl. the machine is making rope in the viedo and can also make cable by using the spools at the back of the machine for a core in the rope.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks