Hello everyone,

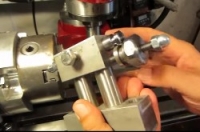

Made RT tailstock for my HV6 rotary table.

It is made for that specific rotary table, not adjustable and can't be used for rotary tables with different centre heights.

Design is very simple. Base and upper block are made from 35 x 35 mm square bar / 304 stainless steel.

Base and upper block are connected with two 22 mm dia round bars (316 s.s.) which are screwed into upper block. (M12)

and tight fit into the base. Ends of these bars are turned to 13.8 mm, protruding out of the base

and serve as alignment for tailstock. (same diameter as width of cross slide slots = 13.8 mm)

(made mistake while measuring, as chuck was not properly centered on RT, so I need to use cutter blades underneath the base as shims)

Centre is made from motorcycle gearbox shaft, dia 15.8 mm. Made groove in the centre to prevent rotating,

even it is not really necessary. Used 8 mm s.s. threaded rod and made nut/knob from 4140 steel

for driving the centre in and out of upper block. Centre travel is 25 mm. Also drilled and tapped hole in upper block to put M10 clamp bolt.

Hope that above will give someone idea how to build it.

Best regards

LMMasterMariner

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks