I have one of those mainland clones of a RF-32 round column mill. You know a "Heavy Duty" Mill/Drill? Anyhow, I never really liked the depth stop mechanism on it. Consequently I rarely bothered to use it either. Which well, let's face it, there's plenty of times when using a drill depth stop is useful.

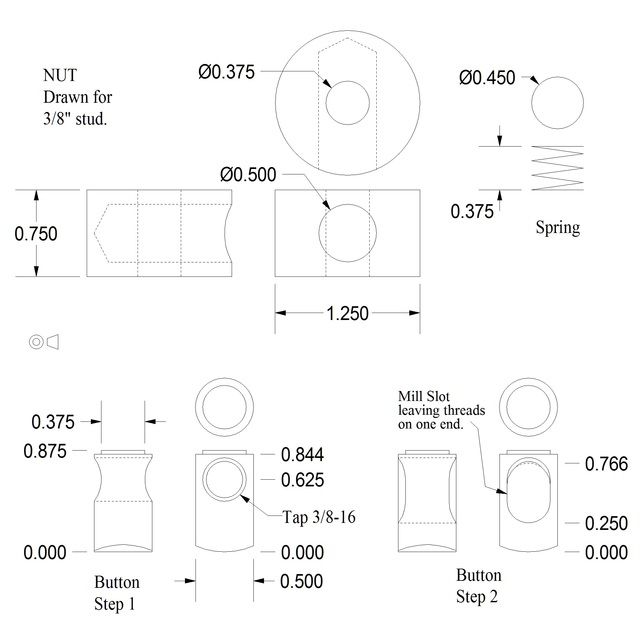

So one day I decided to modify my machine to improve things somewhat. This is what I made.

The one tricky aspect of this was I had to knock down the corners inside the expanding block with a file. Otherwise the nut just wouldn't speed slide. If you make it, you'll see what I mean. Filing that bit of thread out doesn't hurt the nut holding on the threaded rod at all. You really have to put quite a chamfer in it for this to work right. So don't be bashful.

Other than that it is what it looks like. Prepare, and size your stock, then have at it. Making one of these should not take anyone very long. Then you'll actually use your depth stop every time you should. Which means no more drilling through your vises, and nice counterbored holes.

File this one under, I should have done this years ago. The only real downside is you have to leave that crappy plastic cover off. At least I couldn't make this where I could leave that on. I had some ideas, but this seemed more practical to me. I never really used that crappy scale and pointer much anyways.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks