Hello everyone, new to this forum.

I decided to make a sand blaster a few days ago and fiddled all day trying to make a siphon and gravity fed sand blaster... i concluded they are too annoying to make and wont ever be as good as a pressure pot type sand blaster.

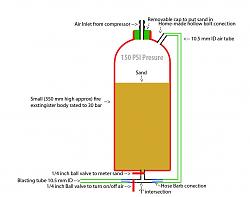

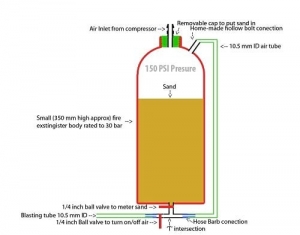

So now i decided to make a type of hybrid... a small pressure pot that is constantly being refilled from our main big compressor. have a look at the image i quickly made to explain.

(click it so you can read it)

Do you think it will work?

Thanks!

MRunknown.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

and compressor fittings are pretty expensive around here). the only part i bought was the inside threaded hose barb for the exit.

and compressor fittings are pretty expensive around here). the only part i bought was the inside threaded hose barb for the exit.

Bookmarks