I am sure this is not a new idea but I cant find one on the forum.

A simple turning job done at one setting (a decent part off will suffice) for this purpose, obviously for live centres only.

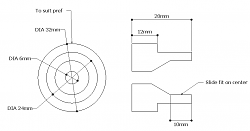

A big help when setting up in the 4 jaw to have something that stays in place while adjustments are made. Its main purpose however is to provide extra security when taking heavy cuts on a part on which you have less than an ideal secure grip.

Like this perhaps.

Or maybe you do not want to centre drill for some reason or perhaps a second op in soft jaws.

When toolmaking I made one for support for turning heavy die housings up to 18 inches dia, I witnessed one of these get away and a 1cwt of metal bowling along the shop is a sobering sight. You know you have got something right when the other turners copy it and its use becomes the norm.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks