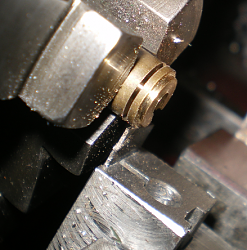

Depending on what you are making sometimes the width of a normal parting tool will waste as much material as the finished part i.e. small nuts etc, some metals are expensive these days so the less of it ends as swarf the better.

This uses worn out all hard HSS blades from my hacksaw machine and its performance has exceeded my expectations provided it is set truly square to the work, the blade has no side clearance

only top rake but lubricated it cuts well and generates little pressure and works best parting to a hole. It is ground to .45 inches wide on my tool sharpener.

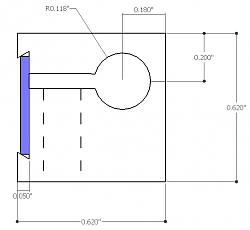

The holder is M/S 2.75 '' long and although not strictly correct the slot is finished using a small dovetail cutter, this pulls the blade in tight and can work within a few thou of the chuck or collet, there is a 6mm tapped spreader hole underneath to help insertion if the blade.

I have also found it useful for circlip grooves etc, the one pictured has a groove milled next to the through hole as I drilled it to far from the edge, not allowing enough spring on the holder, about 1/16'' is about right.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks