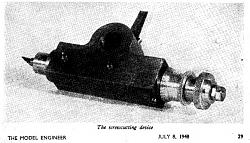

This is my version of K. N. Harris’ “screwcutting device” shown in Model Engineer July 8, 1948. It takes the place of the toolpost on a plain lathe to allow feeding the tool independent of the cross slide in order to cut just with the leading edge while using a threading attachment that drives the topslide.

His was designed for a 90mm center height lathe. Mine is for a Unimat-sized machine with half the swing of his Boley and even less clearance over the topslide so I had to modify some of the original details.

The least obvious of these is the key for the barrel which in mine is a staple-shaped piece of 0.056” piano wire flattened in the middle and held in two close fitting holes in the bottom.

The overall length of my version is about 3-5/16” and the body is 1-3/4 x 1-1/2 x 9/16”. The 3/8” barrel has about 1/2” travel and is split at the end to clamp tools instead of using a set screw.

I use 3/16” round tools in an eccentric 1/4” adaptor sleeve that allows some vertical adjustment.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks