While fumbling around filing a small piece the other day I thought it would be nice to have a small vise to mount on my desk to hold small parts for filing, measuring or whatever, just another hand if you will.

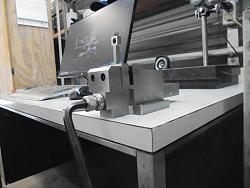

That vise needed to have hard smooth jaws that would not mar the finish on work pieces with a horizontal and a vertical V-groove in the rear jaw for holding round work, the jaws are 2.250” wide with an opening of 5.000”, I was thinking about putting a step in the top of the jaws but sometimes I need to clamp something really close to the top of the jaws therefore I decided against that, so after a couple of days on the computer I came up with this new tool I call the Tool Makers Bench Vise.

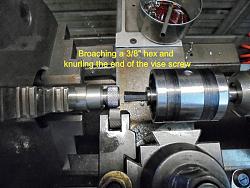

This vise is very rigid in construction and is machined to very close tolerances (like a tool makers vise) with just enough clearance for the moving parts to slide without binding; the sliding jaw of the vise is advanced by a custom made 303 Stainless Steel acme threaded shaft with a hexagonal hole in the center for an allen wrench, the entire vise was made from 1018 steel except for the jaws which was made from O-1 steel hardened and ground.

The vise has four holes in the base for mounting to any surface; the vise is ground flat and square in relation to any surface or edge so it can be used on the milling machine, surface grinder or drill press, but its main purpose is to be mounted on my desk to hold work for filing,

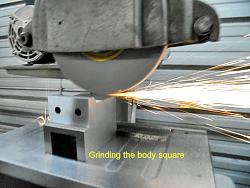

The vise was built with the assistance of two tools I previously made and posted to the Home Made Tools Forum, my Universal Grinding Fixture and Rotary Broach, without those two tools the steps they performed would have been difficult to achieve.

For those of you that are fairly new to the machining world it is essential for your steel to be flat, square with parallel edges before you start any project, if you purchase good quality ground bar stock then your projects will come out with allot closer fits than that of just using a milled bar, if you purchase just milled bar stock you should machine or grind all surfaces to insure squareness and also to clean up all surface imperfections, in my case with this vise I did use just milled bar stock, but I machined each piece all over to insure them to be flat, square and parallel before I started the project.

Below you will find some photos of the machining process along with the completed tool

As Always Thanks For Looking

And Happy Machining

Doug

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

PJ

PJ

Bookmarks