After making the 2-way tool post for the Harbor Freight 9” X20” lathe that I previously posted a few days ago I discovered I couldn’t bore a hole without grinding up a special cutting tool which I thought would be a royal pain in the you know what, so I decided to make a boring bar holder for the tool post.

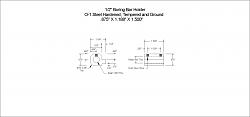

The boring bar holder accepts standard 1/2” shank boring bars (Carbide or HSS) and is made from O-1 steel, the tool holder was hardened,tempered and ground, the tool holder has a 5/16” square tang that fits into either slot of the tool post and is secured in place by the set screws that holds the 5/16” square HSS tool bits.

I want be doing a lot of boring but I know if I didn’t make one I would soon be kicking my butt for not doing so.

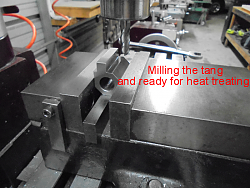

Below you will find a couple photos of the machining process and the finished tool, I have also included a detailed drawing.

As always thanks for looking and happy machining

Doug

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks