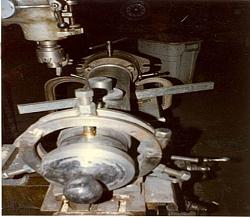

While expanding the photos of my old eclectic computer screen background that I had made of some of my more memorable jobs and designs I stumbled on this one almost hidden like an Easter egg

It is a set up that I used to turn the trunions on a cannon that I was making for a reenactment drill team.

the set up required the use of 1 of my homemade steady rests a super spacer chucked at the bore end and a boring head with the cutter facing inwards on my 3 HP Bridgeport J head mill

the cannon bore was .300 wall 2" bore 4130 tubing embedded in the casting and it weighed around 300 pounds

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks