I hope all of you have seen the fairly new concept of Vapor Blasting or Vapor Honing.

If not, here's a video of the premier US company:

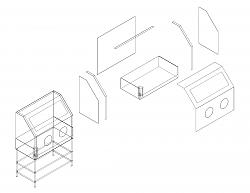

Basically it's a sandblasting booth that uses water to move the media and introduces high pressure air at the nozzle. It's incredible. I have some friends that have a vintage motorcycle shop and cleaning/polishing the aluminum parts is truly a pain. So, a couple other buddies of mine gave me a restaurant sink/counter and a bunch of 3/16" stainless sheets from a demo job. The first thing I thought was, I'm building my own Vapor Blasting cabinet. I don't have $12,000 to buy my own and I want one big enough to put an entire motorcycle frame into (why build small, right?). So, I hope to have it finished soon.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks