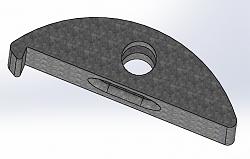

TM 51 this tool is yet another fine example of the often times simplistic approach to HMT's yielding un-imagined use results prior to their addition to ones tool inventory.

I have used similar shaped pieces with a single protruding tang extending a ways out from the flat face which would engage a dibbit or indention to hold extremely odd shaped parts when using my 4 jaw. Many times no matter which way you try to position the part you just cannot get that 4th jaw to engage in a secure position these little cord segments can be used where the grip surface is just too accute to successfully clamp the part the tang will provide a bi-angular clamping force

Last edited by Frank S; Aug 5, 2016 at 09:41 PM.

Never try to tell me it can't be done

When I have to paint I use KBS products

C-Bag (Aug 6, 2016), Toolmaker51 (Aug 6, 2016)

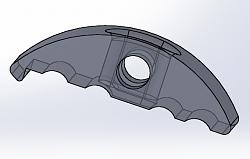

Excellent Frank S! The simple projection engages corner of part; a vast improvement. Great use of mechanics/ physics to rectify an issue. Mine will 'spit' off steeper angles, without some material to increase friction. Mechanical engagement beats coincidental friction every time.

Just used it to machine 'horns' of press stand I hinted at, still not quite ready to post. I sectioned rectangular tubing for a tapered profile for clearance, welded top and bottom back together.

Also reporting on spectacular occurrence during the bandsaw sectioning process. Amazing amount of tension in that tube, spread open like petals when sawn across sides diagonally. Of course, demonstrates residual force, stored energy, from rolling process used to form tubing from flat sheet.

Proves again what is going on in 'our' off topic thread. Experience is priceless. Those who discount it, haven't invested their time to learn; so the value isn't appreciated.

Sincerely,

Toolmaker51

...we'll learn more by wandering than searching...

C-Bag (Aug 6, 2016)

TM 51 if you will note there are also holes drilled and slotted cross angular in the center this adds to the versatility of the cord segment clamp with the use trunion toggles or just bolting it in place on a mill table or it might come in handy

Adding semi circular indention's to the flat face increases the holding possibilities on misshapen parts

Never try to tell me it can't be done

When I have to paint I use KBS products

Yes, serrations direct x-amount of force to reduced area increasing bite. Cross hole is good idea, still blind to the feature of perpendicular slot, maybe to clear an ear-like projection a casting may have?

Frank replied it makes it a hold-down with milling clamps, makes sense. Wring a project for multiple usage, why not?

and then if someone asks, respond "...got more tricks than a monkey in a mile of grapevine".

Last edited by Toolmaker51; Aug 6, 2016 at 07:03 PM. Reason: little update

Sincerely,

Toolmaker51

...we'll learn more by wandering than searching...

Thanks Toolmaker51! We've added your Mill Vise Clamping Aid to our Workholding category,

as well as to your builder page: Toolmaker51's Homemade Tools. Your receipt:

Toolmaker51 (Aug 7, 2016)

I'd add knowing you have a bandsaw, heavy wall pipe works too. Might need to weld a brace to control spreading, but the chord ends make good teeth.

Son of a gun; you can't imagine how pleased this makes me C-Bag! Every time I hear a mandolin...even a banjo.........I write cause Thanks link only works once.

YOU ARE

x10

Sincerely,

Toolmaker51

...we'll learn more by wandering than searching...

Another simple tip to clamping conical shaped parts in a vice, be it a band saw a drill press or a mill, these puppies are a real bear to hold. My solution is I find a humble thick washer with the same outside diameter as the largest diameter of the part in question, then bore the center to fit over the part so as to have 2 supports then I could drill mill or saw where needed.

If the part was short I sometimes add a stop block behind the part to prevent it slipping backwards.

Last edited by Frank S; Aug 7, 2016 at 05:14 PM.

Never try to tell me it can't be done

When I have to paint I use KBS products

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks