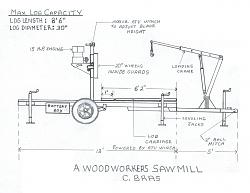

I have wanted to build my own design of a home built band sawmill for as long as I can remember. Last summer I finally got to it. I have little need for construction length lumber. My desire is for shop project wood. For the occasional need for stud length lumber I set my maximum length to 8’6”. This will allow me to use a traveling carriage rather than a traveling arch and still limit the trailer to 18’ including the towing A frame. Here was the initial concept drawing, I like to build by the seat of my pants, according to the many salvaged parts I have collected over the years, so there is not a lot of detail, but the main features are listed.

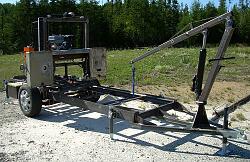

Here the mill is finished except for the paint. Took it outside for a test run. First log is loaded on, with the built in hoist for log handling, a 12" Poplar log.

Cutting a board off of a 10" squared up Birch log.

How accurate is the carriage method? This is a 1/16" slice of Birch veneer. Could have gone thinner, still lots of strength.

The afternoon went without an incident. The result a little less than 200 board feet. Bottom thicker boards are Poplar and Spruce more than half are clear Birch.

All done ready for paint. The intention was to get it painted before the snow set in, but winter came early, and it will be one of the first "to do's" when the warm weather sets in.

This was a big project with close to 300 pictures. If you want to see the complete build here is the link on my blog Hobby Workshop Projects: Sawmill Build.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks