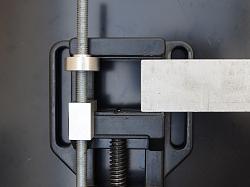

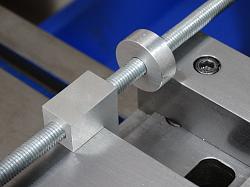

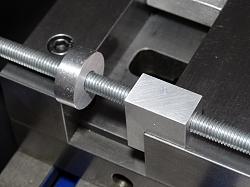

Whoever uses the vise daily, will better understand the usefulness of this device. When attaching a piece to the vise end, an uneven clamping of the jaws usually occurs. This is because there are clearances in the vise, especially when they are very old. This device corrects this problem, providing an even tightening of the jaws and ensuring better fixation of the part. Simple to do, practical and very useful!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks