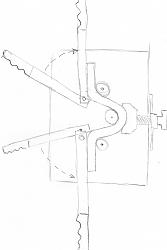

Here's a few pictures of a bending jig I've been working on. It bends the mouth piece for a horse bit. The material it bends is 1/2", 1018 cold rolled mild steel bar. My intention is to make a jig that is easier to use.

Currently, the mouthpiece I'm using in the pictures is a throw away.

As it was at first, it took 3 hands, torch, clamps, wood blocks and hammers to bend the 1/2 stock. I have used this jig many times but it's always been an ordeal to use in the original configuration.

I have just added the parts that hold the top in place and am now getting ready to add the handles to bend the bottom section. I had hoped to use this in my 12 ton press but I don't believe my press is capable of this without heat so it will all be hand work.

I also want this jig to be able to bend different depths and widths etc, hence all the extra holes. I've made different sizes of posts to bend against. What I'm hoping for is to have the 1/2 " stock really hug the bending posts and be a tight bend. You can see where the bottom is completely away from the bottom posts.

I'm open to any and all suggestions ..even if it means having to completely redesign it...

Thanks

Jerry

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks