Hi all!

I'm trying to build a better forge, compared to the previous one that used too much solid fuel.

The ballot was between normal type and V-type, I found this model to study Whitlox Wood-Fired Forges

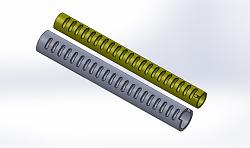

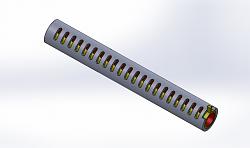

To be honest I don't like so much the light frame, it's insulated with firebrick and fiberglass, I think it's not practical to use and clean with coal or charcoal. It's interesting the regulation of air intake, my idea is to use a long rod to close the holes not used, easy to setup and to clean after use.

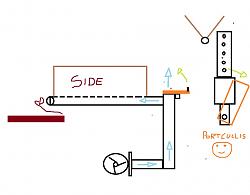

I draw the air valve on my steel table, basically an aluminum portcullis that drains the flow to the air, with an horizontal knob fast to tune.

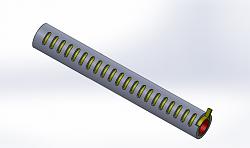

Fireplace lenght is 30cm (12"), 20cm (8") width for the sides, thick 10mm.

Air intake is composite, the central tube is double thick, about 6,5mm, the zone most used, I think

As usual, stick welding.

Some pictures

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks