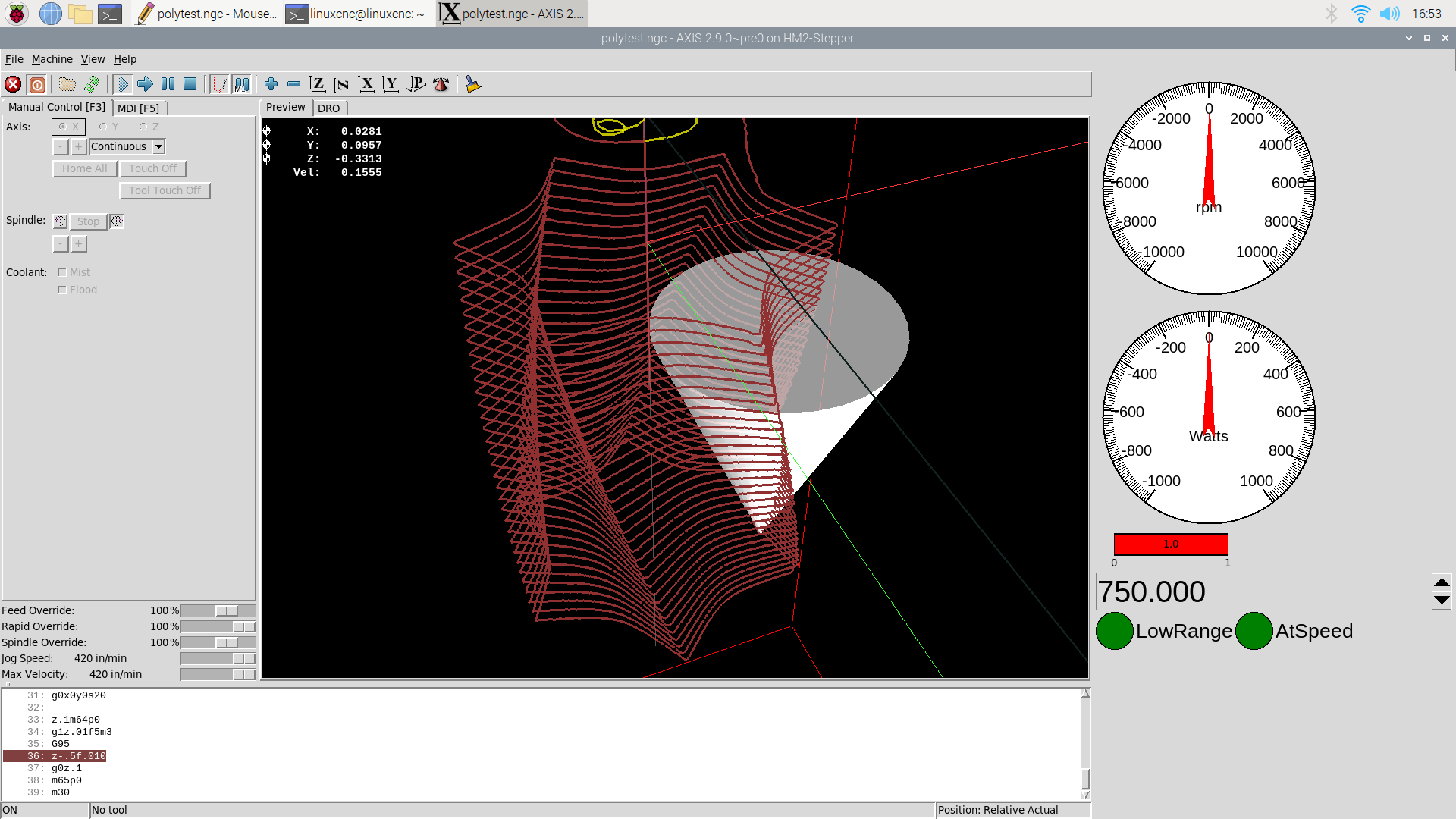

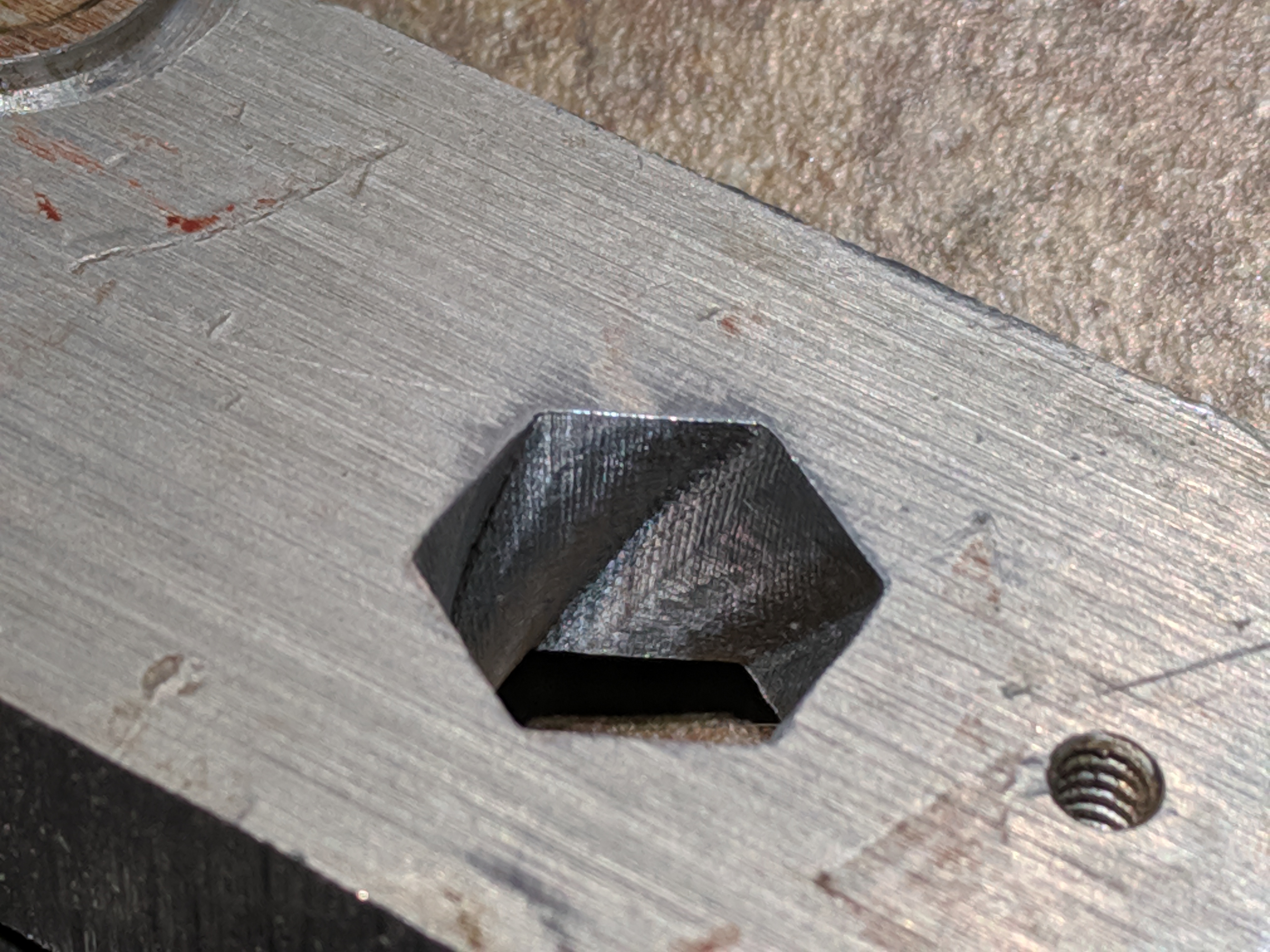

The speeds are dictated by how much acceleration/speed the machine has. If I run the spindle a lot faster faster - the polygon will not look like a polygon...

Hal is linuxcnc's hardware abstration layer. It is sort of the interface between linuxcnc and the outside world. It allows you to create virtual circuits and logic to do as you please.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks