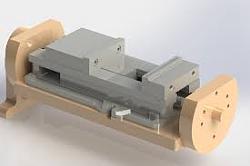

I retrieved 2 pair large tapered roller bearings; specifically to create a trunnion. Only sketching this far has been mental. Bearing ID about 3.5'', OD might be 8''. Best mounting of vice seems lengthwise between bearings, won't center the forces, but would rotate 360 with sufficient centerline height. Of course backside of mount adds table clearance for deeper parts or projections.

Desirable features;

1. To fit 30'' turret mills minimum and larger. All steel for mag chucks [grinders], with jack to withstand deflection of vise plate.

2. Have sine rolls & be graduated in degrees.

3. Mechanically locked rotation, with intermediate drag for setups.

4. Surface & edges drilled/ tapped for clamping matrix along with specific holes for the vise.

5. Slotted for locating keys and dowels.

6. Lifting rings,...to allow setup on surface plate.

7. Haven't selected what vise to build around, but not less than a 6'' lock-down style [Kurt patent] + drilled and tapped for 2 piece table vise as well.

8. Plus what suggestions come along.

Mainly there are two versions. This has it's own support at each end, offering potentially lower profile. The other attaches to an rotary table or indexer 90 degrees to the vise jaws, restriction is based on centerline height of rotating attachment. Both can reference position from the bearing centers.

There is no requirement for numerical control.

This supplants a Pratt & Whitney milling vise that was upright, in that the jaws were vertical while base clamped to table. P&W is #1 of 3 of USA's greatest machine and tool makers, in my regard and DNSHO [Definitely Not So Humble Opinion]. Waited decades for one to appear...they are rare and apparently owners still cling to them. This trunnion will do all the P&W will and more. My AngLock copy is a version without clamp holes or coolant trough. It's slotted to clamp flat or upright, kind of makes up for the P&W quest.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks