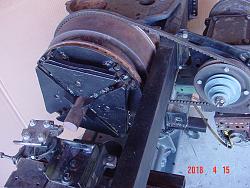

This is a homemade 4 jaw chuck for my "homemade metal working lathe". The foundation is a Ford disk brake rotor. the rest is all scrap metal.

This is my version of Pat Delany’s Multi Machine. see multimachine-Wikipedia.

This is an example of a home made metal working lathe. It is constructed using recycled engine blocks & auto parts. I have focused on keeping the cost to as near $0.00 as possible The idea I have is to make this lathe using common recycleable auto parts and be assembled with minimum tools. So far the parts used are 2 Mopar slant 6 blocks, a 3/4 ton Chevy rear axle spindle & hub, a 3 speed car transmission, a Chevy V8 head.

The multimachine is built using vehicle engine blocks combined in a LEGO-like fashion. It utilizes the cylinder bores and engine deck to provide accurate surfaces. Since cylinder bores are bored exactly parallel to each other and at exact right angles to the cylinder head surface, multimachine accuracy begins at the factory where the engine block was built. Parts will be perfectly aligned and at an exact right angle to the face (head surface) of the main engine block that serves as the base of the machine. Blocks have a multitude of tapped holes for mounting accessories. The multimachine uses a unique way of clamping the engine blocks together that is easily built, easily adjusted, and very accurate.

I am not going to put in a lot of specifics and measurements since most likely your project will become different because of different parts being used. I will post more as the project progresses.

I relinguish all liability and you will assume all liability & responcibility for any project built. Any comments or advice are appreciated. I will post more as the project progresses. More pics are at "flyingkmachines.wordpress.com My email is "flying.k@juno.com. I'd love to here from you with your thoughts of the project. Paul

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks