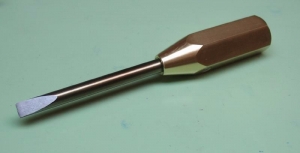

Homemade Flathead Screwdriver

TOOL:

BUILDER:

Adventures in Watchmaking on watchmaking.weebly.com

DESCRIPTION:

Homemade flathead screwdriver machined from brass hex rod and drill rod. Blade is hardened and tempered.

RATING:

(0)

Dec 26, 2016 2:13 PM

Toolmaker51

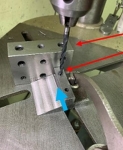

This makes a quality and efficient driver bit. On occasion where I need an odd bit, quick results are had by milling both sides of center-line against a four flute endmill. This produces a parallel form instead of a wedge. A simple calculation reveals the offset needed to generate thickness desired. If you have indexing tools, that allows conventional milling on both sides. Basic figures needed: rod diameter minus bit width plus 1/2 cutter diameter. Generally the 'length' of cut is about 2x depth of slot.

Many assemblies have uniquely sized slots, especially shotguns. When a vintage example is engraved, all manner of precautions are taken to preserve that fastener.

Rate this build:

CATEGORIES:

TAGS:

LEVEL OF DETAIL (1-5):

3

FILES:

Newest Forum Posts

- Excavator smoothing excavated surface - GIF by Altair on 2024-04-26 21:51:01

- Multi-insert milling cutter - GIF by Altair on 2024-04-26 20:27:01

- Getting a tandem axle truck unstuck - GIF by Altair on 2024-04-26 19:13:01

- Hydraulic & Hydrostatic Dump Truck by Jon on 2024-04-26 16:31:03

- Sliding driveway gate - GIF by Altair on 2024-04-26 15:42:01

- Kinetic log splitter - video by Jon on 2024-04-26 15:22:20

- Lathe tailstock turret - video by Jon on 2024-04-26 15:21:52

- Knife from bike chain - video by Jon on 2024-04-26 15:21:23

- 1776 micrometer - video by Jon on 2024-04-26 15:21:00

- Router table - video by Jon on 2024-04-26 15:20:42

DIY Flathead Screwdriver - comment on how to build a Flathead Screwdriver - 1 comments

Toolmaker51 says:

Dec 26, 2016 2:13 PM

This makes a quality and efficient driver bit. On occasion where I need an odd bit, quick results are had by milling both sides of center-line against a four flute endmill. This produces a parallel form instead of a wedge. A simple calculation reveals the offset needed to generate thickness desired. If you have indexing tools, that allows conventional milling on both sides. Basic figures needed: rod diameter minus bit width plus 1/2 cutter diameter. Generally the 'length' of cut is about 2x depth of slot.

Many assemblies have uniquely sized slots, especially shotguns. When a vintage example is engraved, all manner of precautions are taken to preserve that fastener.

Related Homemade Tools:

Signup for our newsletter and get the 186 More Best Homemade Tools eBook free!

- BuildThreads Network:

- HomeMadeTools.net

- BikeBuilds.net

- FordBuilds.net

- ChevyBuilds.net

- 4x4Builds.net

- BoatBuilds.net

- PlaneBuilds.net

- CabinBuilds.net

- GarageBuilds.net

- MuscleCarBuilds.net

- HotRodBuilds.net

- GMBuilds.net

- TruckBuilds.net