I pulled my lathe apron apart for maintenance and made this 3-D printable cover for the gears in the apron.

I put the download up on Thingiverse.

https://www.thingiverse.com/thing:5871566

Anyone that needs one and doesn't have a 3d printer, PM me. I'd be happy to print you one.

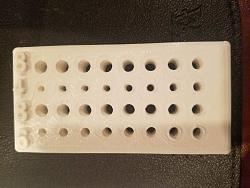

Question: How do I know how much clearance to put around a screw hole when designing a part? I've read about press fits and slip fits in the Machinery's handbook, but I'm struggling to connect that hypothetical knowledge with real-world designs. Specifically, this part uses M4 screws for mounting and I added (I think) 15% of the diameter for clearance around the fastener. Still, I had to drill out the cover get the screw to fit. What am I missing?

I can (and will) brute-force the problem by printing an array of holes of various sizes for my next project, but I'd like to understand the "right" answer too.

Thanks all.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks