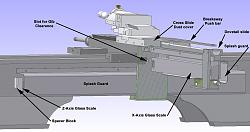

Ebay and other websites are alive with Chinese DRO's at a very reasonable price, typically under $200. I decided it was time to upgrade my ancient Atlas 10X36 lathe and purchased one. I opted for 150mm travel on the cross-slide and 450mm on the carriage. The DRO I purchased was a 3Y Model KL2ADR two axis display with lots of additional features such as a calculator and options to store hundreds of tool offsets.

The Glass slide for the carriage (Z-Axis) can be mounted on the backside of the lathe bed, and installation is fairly straightforward.

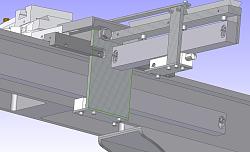

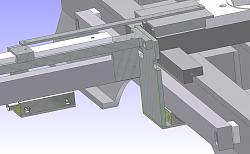

The Atlas lathe does not have much room for a full size glass slide on the crossfeed without compromising either the tailstock access to the part being turned. The solution I came up with is to install the crossfeed glass slide behind the carriage using a "Tee" shaped bar bolted to the two 3/8-16 threaded holes intended for mounting a milling attachment or other accessories. I incorporated a dovetail slide to keep the sensor parallel and the correct spacing from the slide, and added a "push bar" from the crossfeed to the dovetail slide to get the required linear motion. I am a little concerned that using power feed on the crossfeed might drive the glass slide beyond its limits, causing damage, so I am working on a break-away connection just in case. The images attached should provide enough ideas for anyone wanting to use this mounting method to fabricate the needed brackets. This technique can be adapted to other small lathes as well.

After building and testing this design, I discovered a small error in the X-axis assembly. The dovetail slide had a tiny amount of play which resulted in an error of about 0.002" in 1 " of travel since the sensor was mounted on an arm below the slide.

The new design has the sensor head mounted directly on the slide with the glass scale mounted above. This results in a much improved performance. I also changed the dovetail slide to a ball bearing slide since I had a spare left over from another project. Having the sensor being directly pushed and pulled eliminates any error due to angular motion in the slide assembly. The glass slide was mounted above the slide assembly to reduce the possibility of coolant or cutting fluid or chips getting inside. The attached figures show the details of the modification.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks