Originally Posted by

FEM2008

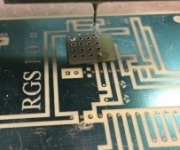

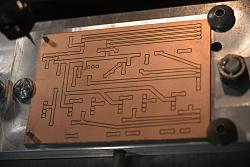

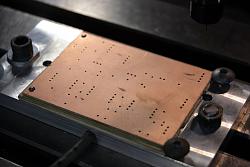

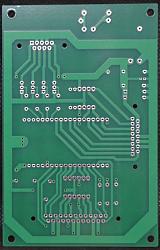

For homemade PCBs, I've always done the layout with an etched hole in the center of the pads. It does indeed help with drill alignment. But, very small drill bits flex and wonder sometimes, especially if I'm not being careful. If there a lot of holes to drill, I tend to get sloppy towards the end. It is good enough for most components though, even IC pins. But as you noted, sometimes more accuracy is needed.

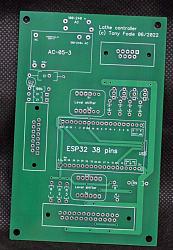

It's probably been 3 years now, but the last board I did, I, sent to a fab house in China, and for just a few dollars, I got 5-blank pcbs complete with silkscreen. The quality was excellent, and best of all, I did not have to deal with the etching solution. The only complaint was it took a couple of weeks. For $20 more, I could've had the PCBs in in about 4-days, but that was double the cost of the PCBs themselves.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

I have etched many a PCB and I know exactly what you mean about drilling holes. it's also quicker than trying to do it on a mill.

I have etched many a PCB and I know exactly what you mean about drilling holes. it's also quicker than trying to do it on a mill.

Bookmarks