Hi

Fabian here from the UK.

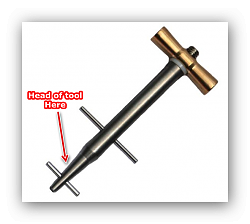

I'm trying to build a similar tool to the wire tightening tool 'Clamptite' that's sold in the United States as I'm using a thicker wire to strengthen a load of garden fencing that was damaged by the left overs of one of those US hurricanes that's hit the US coast.

The 'Clamptite' tool I own is too small for this so I thought I'd have a go at making one which will take the much bigger gauge wire.

Could anyone here tell me if the part which is arrowed has been machined on a lathe out of steel or has it been cast in a foundry. The body of the Clamptite is copper , but the top or head part is an alloy or stainless steel.

Please forgive my bad description as I'm not an engineer, just a guy trying something new.

Thanks a lot.

Fabian.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks