I got an old Hougen magnetic base portable drill press with a broken spindle. The part is obsolete. I have searched extensively online for a replacement with no luck.

It is just a shaft with a couple of different diameters, 1 threaded end and a Woodruff key seat. It has a couple of precision ground spots that run in needle bearings. Those will be the most challenging for me. I am game to try it with my tool post grinder. The original is drilled and taped as you would use on a reversing drill, but this one does not reverse. Since the original broke in the threads, I am planning to leave the threaded end of the spindle solid for additional strength. The original is broken clean, very fine grain with no distortion. I am sure it was heat treated.

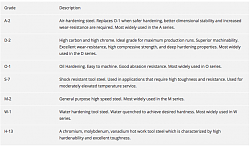

From what I have read so far, A-2 tool steel appears to be and appropriate material. I assume the original was heat treated, but I have no idea how much to temper it.

I have confidence I can do all of the required machine operations. I plan to turn the rough sizes, maybe +0.005" then heat treat and finish the critical sizes by grinding.

I have basic treating capability which I have used for chisels and cutting tools etc. I am thinking the most critical heat treat operation will be how much to temper the part.

Any heads up will be appreciated.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks