I say Inverse rather than internal or inverted since the part than needed clamping was being contrary and defying every other reasonable means to hold the pieces.

My mechanic neighbor had a hose made up somewhere and the guy that installed the fittings said I think these are the same as the ones on the bad hose. Ha, ha, famous last words Well at least he had the diameter and the O ring sized correctly but the height of the split flange fitting he installed were different not being the same brand of fitting.

Billy brings me the flange clamps for me to machine .030" off if them. I said just a minute I'll check my stock, I pulled out 5 packages of flange clamps with the4 correct height but the wrong hole centers by a 1/16 of an inch. leaving no choice but to machine the ones he had to fit the new hose end.

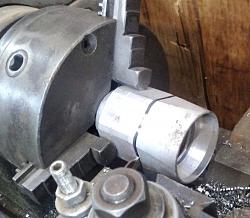

I started out I thought I could clamp them down to the mill table and just mill off the face of the flange but there were only 2 machined surfaces on the parts the face and the depth of the bore so 86 that idea I then thought of the way lantern chucks hold things only I needed to hold the face of the counter bore from the inside so I could machine the flange face I also felt I wanted another machined surface to clamp on to so I flipped the flanges over on the mill table clamped them face down and made a light cut on the heal or the bump in between the bolt holes.

To make the chuck I used a much larger reusable hose end fitting and machined it down to size.

I parted off part of the outer fitting nut then machined it down to what I needed

I then cut 2 3/8" coupling nuts in half and welded the 4 pieces to the flats of the outer nut now I could tighten the nut to the flats I machined on the humps I tightened a hose clamp around the perimeter of the flange clamps to serve as a fly off prevention band, adjusted the 4 bolts to align the edges of the 2 pieces measuring off of the face of the chuck I then made several light cuts until I had removed the required amount from the flanges

And this is why I named it an Inverse lantern chuck. If anybody knows a better name for it I'll gladly adopt the new name

Before and after of the chuck

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks