I lived with the plastic gears on the mini mill for a while before they broke:

More details and images showing what you're likely to find in one of these gearboxes: Mini Mill Gearbox – glue-it.com

I ordered metal gears from the USA (I live in UK) and installed these:

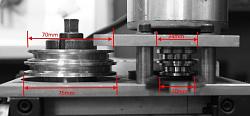

These were ok, but the noise was high and you could still feel the hammering of the cutting tools and so I decided to make my own belt drive:

I've written an article on this conversion with some dimensions that should allow you to modify this idea for your own milling machine: Mini Mill Belt Drive – glue-it.com

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks