My usual method of using a tap on the lathe was to chuck the tap in the drill chuck, then turn the lathe by hand until the tap started to turn in the chuck. This would get the tap started straight and deep enough that I could then use a traditional tap wrench. However, I only have a couple inches of swing, so it was hard to use the traditional tap wrench.

I already have a tailstock die holder that has worked really well, so I found a way to adapt that to tapping.

One of the Big Box places had a tap wrench that had 1 inch across the flats for a hex wrench, a hole for a 1/2 inch socket, and a hole for a 1/4 inch tommy bar.

I turned down the 1" hex to a 1" circle so I could mount the wrench in my tailstock die holder. If needed, I can still use the 1/2 in socket wrench or the tommy bar. The 1" wrench seems like an invitation to break a tap any way.

Before I turned down the hex, I used the hex to index dimples at the proper level so my tailstock die holder could keep the wrench from turning.

I used a 1/2 copper coupling, split length wise, as a perfect fit for soft jaws to grab the threads on the tap wrench so I didn't mar them while doing the interrupted cuts on the hex.

The first photo shows the dimples made while the end was still a 1" hex - you can also see the original hole for a tommy bar.

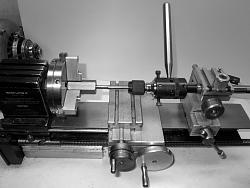

The second photo shows the tap wrench mounted in the tailstock die holder, ready to go.

This wrench works for #4 through 1/4 taps. They offer another for 1/4 - 1/2 taps, but I don't know if it still has a 1" hex or something larger.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks