Sounds intriguing, Tony - any follow-up posts with pics, per chance?

Any data on the ball screw cross slide enhancement would be much appreciated, at least by me...

ATB

Johan

Grinding tapers using the compound was one of my objectives so that drove the design along with budget. I wish I had a better chuck mounting system but the two setscrews on the neck of my screw on chuck do a reasonable job of keeping the chuck on when run in reverse. I do check that it's staying tight periodically though.

That's good stuff Tony and I'd appreciate it if you continued it in another thread focused on it.

If you can't make it precise make it adjustable.

Don't worry I would start new posts for any original work as I always do. I have no intention of hi-jacking your post, I was simply responding to you in my first post and Johan in the second.

When I first joined this forum I asked about the policy for responding to posts and whether it was the done thing to stay strictly on topic as some more rigid forums insist on. I was told in no uncertain terms by several established members that is was quite usual and appreciated to wander off topic as some of the most interesting threads had formed in that way. The wider the topic spread in a thread the more attention is drawn to the original post.

olderdan (Jan 11, 2021)

Nice work Tony, I am particularly interested in your bayonet chuck mounting conversion. I have long thought of a way to convert my screw on chucks while keeping the original mandrel (plain bearings) judging by the marks on your mandrel it would appear to be the original. I am thinking modern adhesives may provide the answer but any ideas would be well received.

olderdan (Jan 11, 2021)

Saltfever (Jan 16, 2021)

Nice Tony! I’m kind of confused by the term “bayonet”. It kind of looks like the beginning of a Long style or “D” type taper mount. Or were you referring to sumptin else?

Your ball-screw conversion, as well as your very unique thinking for the mount, deserves its own post. Very much looking forward this work.

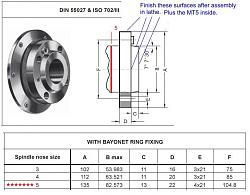

As I said in my original post here. I shall be doing dedicated posts on on each of the three things mentioned, but to answer your question briefly. My preference is for the long nose taper style but that would have required making a lot of swarf from big lumps of steel or CI for the chuck backplates, whereas the D style or bayonet only needed a minimum of work modifying the existing backplates. "Bayonet" is not my term it is a recognised standard. The taper dimensions etc. are mostly the same as a D type. There will be full details in the dedicated post. Meanwhile

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks