I've been working on the brake set-up for my BadAst Astro Van build. This is a bracket I developed to hold the Wilwood Prop Valve I will be using.

With the valve bolted on. Clear access to both of the outlets on the bottom of the valve and it's not going anywhere. Once the lines are made and bolted in it will be pretty solid.

I ran into a bit of an issue with the prop valve placement. It is too low. The outlet for the front brake line I need to plug is to close to the bracket underneath it. I didn't think it would be a problem finding a low profile inverted flare plug to fill the hole but I have found nothing that will work. The regular plugs are to tall and I do not want to remake the bracket OR the hardlines, so.... I will make a low profile plug.

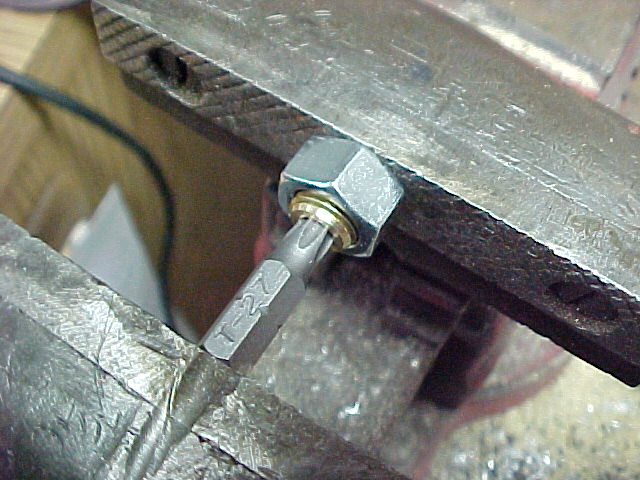

I puttered around in the shop the other night trying to figure out how to tighten the plug and came up with this. I bored a .173 diameter hole in a test piece of aluminum.

Then I used a short Torx bit to "broach" a hole for the driver. I started it with a few taps from a hammer to make sure it was straight then just pressed it into the test piece with the 4" vise.

Continued in next post.

Mark

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks