Bolts are a good source of round stock. I never throw away a bolt, even old rusty ones. They are not rusty on the inside. Be sure to note the grade of the bolt if you are making something strength critical.

Today I found this tool I figured I would never need again in the drawer where I keep old bolts, etc.

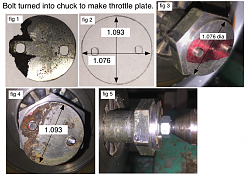

I made this about 4 years ago to repair an old Gravely walk behind garden tractor. It had been sitting under a tarp for a while. A hole got worn in the tarp and let water get into the carburetor. After sitting in there over a number of years, the throttle plate corroded so it would no longer close the carburetor throat enough to allow the engine to idle properly (fig 1)

The only way to get a new throttle plate was to buy a whole new carburetor… or make a new plate. The plate was not round but rather like two 1/2 circles stretched apart just a little. (fig 2)

I used this bolt and made a special chuck. Faced the head. Turned part of the head round to the match the 1.076 dimension of the original throttle plate. Drilled two holes to match the hole spacing in the throttle plate. Pins are from a broken 1/8 drill bit.(fig 3) The pins drove the new throttle plate (original is shown in fig 4). In use, an appropriate size plate was drilled to match the original holes then pressed against the chuck by live center in the tail stock.(fig 5) A hex nut was used to cover the point in the center to hold the plate firmly against the chuck.

I turned the new plate to 1.093 diameter matching the dimension of the original. Then hand filed the sides, using the turned portion of the “chuck” as guide.

Can’t show the new throttle plate, it is in the tractor.

Click to enlarge

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks