I all

I have an old Vigor sewing machine (maybe from 1920), in good external condition.

I cleaned and oiled the links, the action is smooth but the machine is still not working.

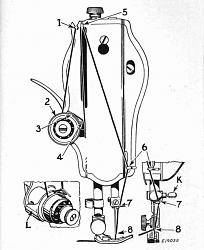

I'm not so sure about the path of wire, nor if the shuttle is ok

When I try to advance the wire doesn't make a turn around the shuttle and makes a tangle, causing wire breakage. Maybe it's a timing trouble, or worn parts

Have some advice? I'm a noob of sewing machines, but I want to learn how to use

Saluti

Stefano

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks