If you looked thru my bead roller thread here is the reason for all of the upgrades. In the process of pulling my '56 wagon apart for rust repair and repainting I removed the C pillar covers. These are held on with a metal plate that bolts thru the C pillar.

The lower 3rd of one of them is badly rusted.

I was going to just replace this portion but, now that the bead roller is capable of making this shape, I will just make a whole new plate.

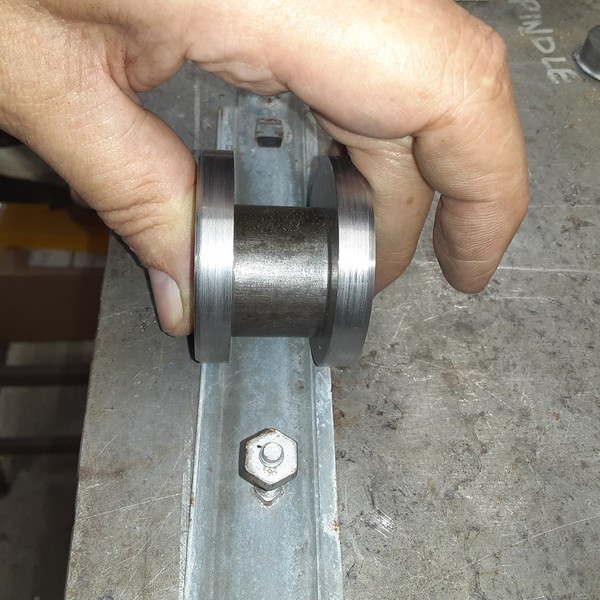

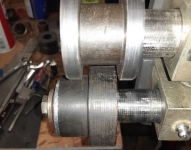

I made a couple of washers out of 1/4" plate to make the flange portion. I used a Rota-broach to bore the initial hole. An .875 dia broach fits my HF roller shafts very nicely.

After chunking these out on the bandsaw I knocked the corners off with a cut-off wheel and a grinder.

I turned a mandrel out of a chunk of scrap aluminum, drilled and tapped it for a 3/8-16 bolt and spun the washers down to a 2" diameter on the old Smithy lathe.

These needed a sharp edge to make that corner of the flange. I put a 45 on the other edge to make them reversible for other uses.

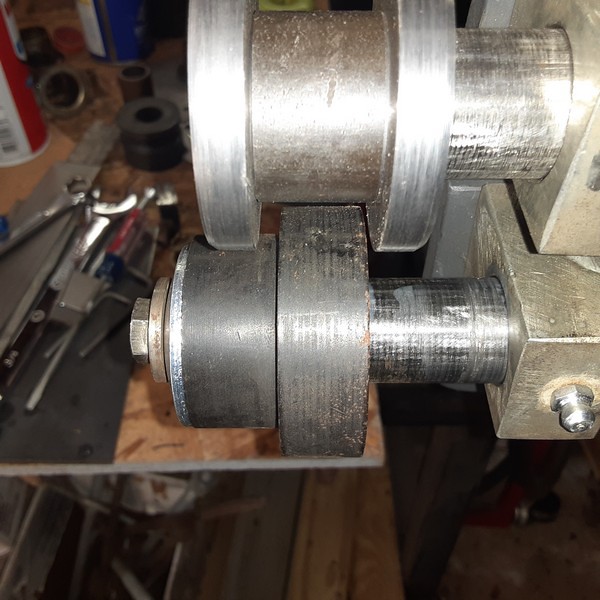

A spacer was made out of DOM 1 1/4 tube to set the width. I ended up making two of these as the first one was a bit too narrow.

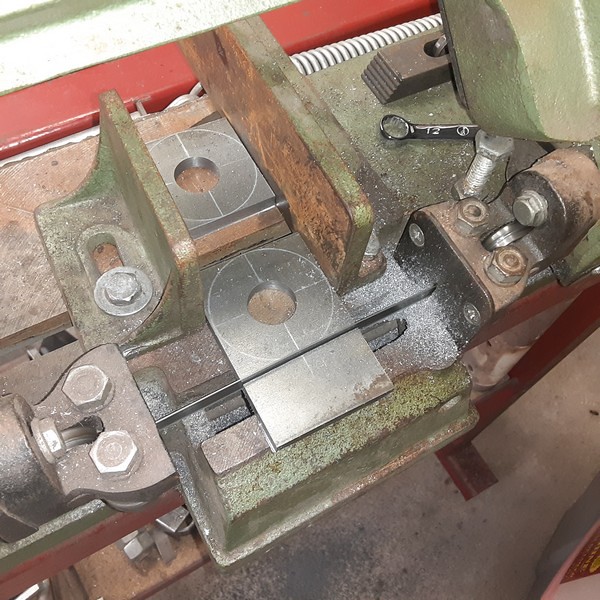

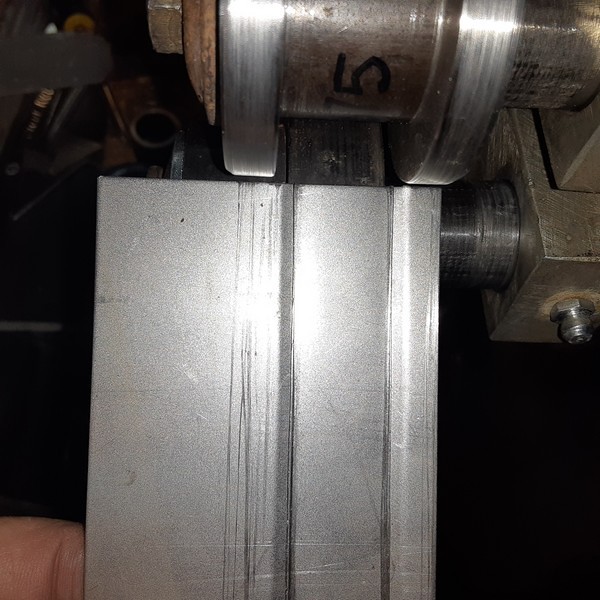

Set up in the roller. Being able to adjust the spacing with the top bar was a big plus! I used one of the standard forming dies in the lower position to make the "bump up". It was a perfect fit to the inside of the original plate.

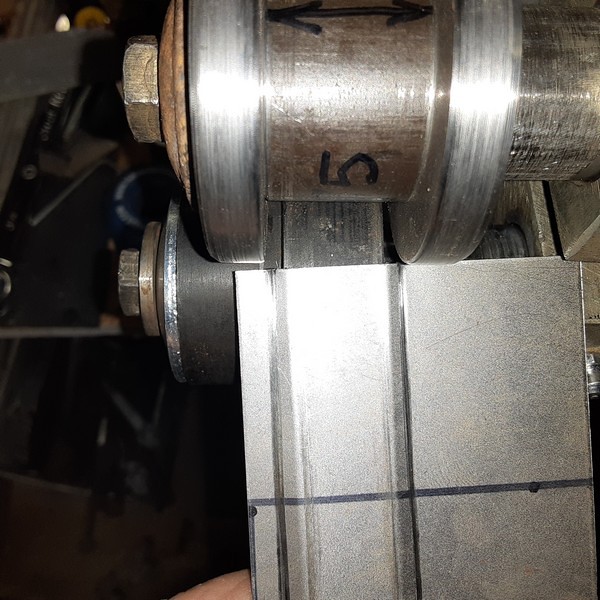

I ended up running a couple of test pieces. The first one was a bit narrow (not that it really matters) and another with the wider spacer.

The pieces turn out very nice after a few trips thru the dies. The initial forming takes 6 or 7 trips, sneaking up on the full depth.

As you can see the initial forming puts a bit of a tip into the flanges AND a bit of a curve into the length of the piece.

To flatten the flanges out and remove the curve I turned the piece over and ran it thru the dies "upside down". I backed off the pressure and kept increasing it until the flanges came out totally flat. Only took 3 or 4 trips to get it flat.

This will work great and gets me a piece that is not reproduced for these cars...

Mark

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks