My domestic CJ18A lathe is lacking a gearbox, and its finest feed comes down to a little less than 0,1 mm/ turn.

Changing the plastic gears is a PITA for me - solely reserved for gear threading these days, as I got myself:

"Cheapnik Power Leadscrew", of DIYSwede's own iSore™ brand: -"As unique in design as its unobtainable!"

Being cheap, I'm always on the lookout for stuff "that might come in handy" at my job or my "Walk-in Closet Workshop" at home.

Amongst other fun things being condemned to the dumpster at work are the electric office table lift units, usually with electronics or breaker faults.

These worm-drive motors are pretty rugged, albeit with usually lousy duty factors in the 10-20% range.

I've sourced over a dozen thru the last years, from the rugged Swedish Ankarsrum KSV 5035, 100% DF drives

(powering cars' & trucks' windshield wipers for decades), via the German Ketterer mid-range 20 % DF series, down to IKEA's cheap italian ELVI drives.

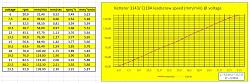

Let's check out the "Ketterer 3146 datenblatt": of which I have half a dozen (motors, that is - not data sheets!).

Particular for this one is the 6 mm hex thru-hole drive, its max 24 V and 90 rpm giving the table a 4 mm/sec and 1200 N lift with its 3mm pitch screw... For my leadscrew's 1,5 mm pitch, the speed would thus be halved and the force doubled...

-Lessee some measurements:

So, data above are actual leadscrew values in a motor mockup when powered by 2 Dell DA-2 series connected PC PSUs,

that can crank out 18 amps, and a cheap BangGood 90V, 15 A, 1kW PWM module

-Yeah I know - the motor will weld itself shut, strip the half-nuts and/ or buckle the leadscrew in the meantime, before the fuse blows.

My speed values differed from the manufacturer's specs - but it'll do the job, it is small and easy to fit in,

and if I don't take crazy DOCs at wild feeds it'll have a better duty factor than stated for office table duty.

A bonus is the near silent drive I've got, in contrast to so many DIY builds out there on the web,

using a gearbox drive powered by a small high-rev Mabuchi motor, having a fairly high noise level I don't like personally.

Design considerations: Simple in/ out dog clutch drive to the leadscrew end locknut, out-of-the-way placement, screw reverse initially not necessary.

To be honest - I've used the thing since x-mas in this crude mockup state, not finishing up with a project box for the MCU yet...

No more of my yakking- here's the pics:

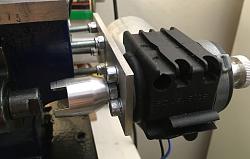

Left pic: No-frills attachment thru 4 x M5 bolts tapped into the bed end, small plate attached onto which the drive is bolted.

Red safety (yogurt can cap) still in place.

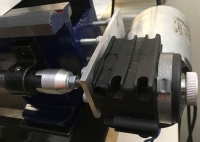

Mid pic: Clutch disengaged: just a piece of Al turned, threaded M5 and milled in the lathe, the 6 mm hex bar threaded M5 at both ends, a tiny Neodymium magnet keeps the clutch locked on, and a found knob was turned and loctited to the other end.

Right pic: clutch engaged - and has stood up thru time, as the lead screw's end nut now is tightly locked, it won't jam the bearing block any more.

Motor is hot to touch (but not at its Curie point yet) after an hour of rebar coarse turning. I have several of this motor if needed...

-Ah, yes! I forgot to tell you - as its all done from scrap pieces, it didn't cost me anything, apart form app 3 hours of "work"/ tinkering.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks