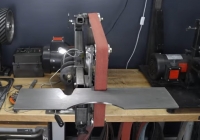

Homemade 2x72 Belt Grinder

TOOL:

BUILDER:

swordfish on bbs.homeshopmachinist.net

DESCRIPTION:

Homemade 2x72 belt grinder featuring a 3-cone pulley step system and 2 belts. Incorporates a variable speed motor and a 12" rubber wheel.

RATING:

(2)

Jun 15, 2018 8:55 AM

Anonymous

Nice but I might have made a straight tall sanding area that was vertical, or depending on what this is used for looks like sharpening knives made it so you could change the bottom horizontal side to vertical or horizontal positions. This could be done pretty easily with a pivot point at the drive wheel. and lock into an up or down position you could also have used a dc motor off a treadmill and added a rheostat for speed control Most of these motors are 1.5 to 3.5 hp and can run high speed or low speeds with less loss of power, that's a AC motor and without pullies you can't change the speed without loosing motor power unless you but a v belt type pulley system on it. I'd also think about safety guards.

Rate this build:

CATEGORIES:

TAGS:

URL:

FILES:

Newest Forum Posts

- Plastering faux stone wall - GIF by Altair on 2024-04-27 19:13:01

- Automatic retractable car cover - GIF by nova_robotics on 2024-04-27 18:39:30

- Lathe tailstock turret - video by dbat74 on 2024-04-27 18:23:17

- Watchmaker’s Sensitive Drill Press - Restoration, Rebuild or Something in Between? by Dimitris Polychronis on 2024-04-27 16:55:22

- Making granite countertops - GIF by Altair on 2024-04-27 15:42:01

- Stab and bludgeon-proof body armor demonstration - GIF by TheElderBrother on 2024-04-27 14:33:04

- Man loses control of cart - GIF by thevillageinn on 2024-04-27 13:50:20

- Extra long chips from production machining - GIF by Altair on 2024-04-27 12:56:01

- Mortise and tenon felling cut - GIF by nova_robotics on 2024-04-27 12:07:28

- Instagram models - GIFs by InstagramBot on 2024-04-27 12:01:01

DIY 2x72 Belt Grinder - comment on how to build a 2x72 Belt Grinder - 2 comments

Anonymous says:

Jun 15, 2018 8:55 AM

Nice but I might have made a straight tall sanding area that was vertical, or depending on what this is used for looks like sharpening knives made it so you could change the bottom horizontal side to vertical or horizontal positions. This could be done pretty easily with a pivot point at the drive wheel. and lock into an up or down position you could also have used a dc motor off a treadmill and added a rheostat for speed control Most of these motors are 1.5 to 3.5 hp and can run high speed or low speeds with less loss of power, that's a AC motor and without pullies you can't change the speed without loosing motor power unless you but a v belt type pulley system on it. I'd also think about safety guards.

Related Homemade Tools:

Signup for our newsletter and get the 186 More Best Homemade Tools eBook free!

- BuildThreads Network:

- HomeMadeTools.net

- BikeBuilds.net

- FordBuilds.net

- ChevyBuilds.net

- 4x4Builds.net

- BoatBuilds.net

- PlaneBuilds.net

- CabinBuilds.net

- GarageBuilds.net

- MuscleCarBuilds.net

- HotRodBuilds.net

- GMBuilds.net

- TruckBuilds.net